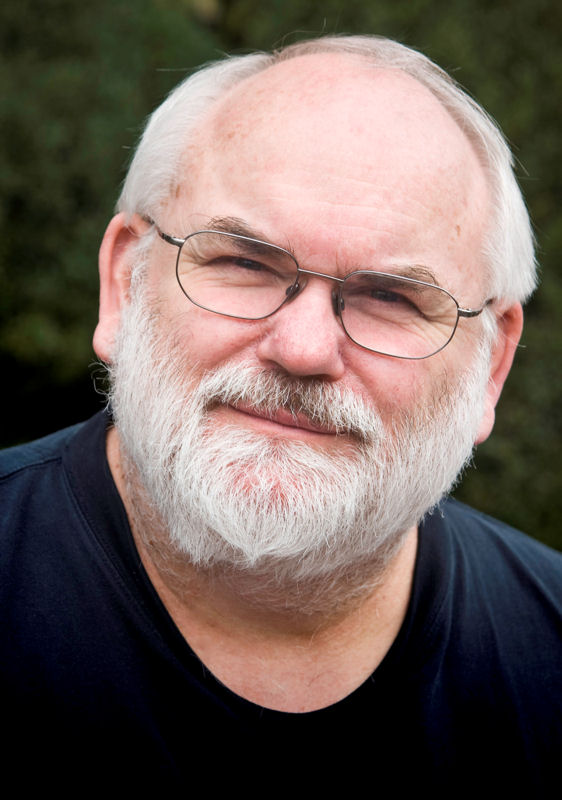

| John Seldon, WEF Member and Founder of Temporary Operations and Maintenance Inc.

John Seldon, a Water Environment Federation (WEF; Alexandria, Va.) member since 1980, is founder and president of Temporary Operations and Maintenance Inc. (Port Burwell, Ontario) and a principal of Envir-O-Site Inc. (Sarnia, Ontario). During his career, Seldon has focused on optimizing municipal and industrial solids collection and dewatering systems. Since entering the wastewater field in 1973, Seldon has

|

An operator in a water resource recovery facility carries the primary responsibility for protecting our receiving streams from contamination and, for many water takers, our potable-drinking-water quality sources. Because of this enormous responsibility, they must be fully capable of operating all aspects of their facility’s characteristics.

A wastewater operator’s working paradigm

During my early career, I was responsible for the operation of a municipal water resource recovery facility when the facility’s basic process data were entered daily on a monthly summary sheet. These helped generate an annual data summary. All this material was available to the city’s consulting engineers when current and recent historical operating information was needed for future facility design. This meant it was not necessary to send engineer-supported technologists to gather ongoing process information or to verify the quality of data provided, saving both time and money.

Also, working as an independent contractor, I was hired to gather basis-of-design data for a private-sector firm looking to design a new wastewater treatment system that would capture mud solids from its potato-washing system. Although this firm had individuals responsible for the basic fluming/settling process and arranged for mud-solids removal through a private-sector hauler, historically no process data were collected from the ongoing operation. As a result, the firm hired me to gain insight into the mud-solids collection-system efficiency by collecting basis-of-design information.

Both examples exemplify a need to understand treatment process parameters through effectively sampling and measuring the process stream characteristics to secure the information engineers need for process design. Much of this work is reduced to arithmetic values. The person gathering information has to know how to quantify process characteristics and should have a fundamental understanding of the values themselves. If presented with a value for a process step, this person should sense whether the value is an anomaly.

Arithmetic fundamentals and an ability to summarize information on a basic statistical level are crucial for a comprehensive understanding of any wastewater treatment process. Operators should have expertise in these areas of process management.

Focusing on different areas of treatment

Water resource recovery facility design is an engineer’s world informed by microbiology, chemistry, hydraulics, instrumentation, surveys, and receiving-stream assimilative capacity. Engineers may need to access specialized knowledge from experts, such as in the areas of microbiology or stream ecology. These fields can inform the engineering required to best design a water resource recovery facility and may not be core areas of academic study or practical field experience by engineers.

Operators should be certified in the different aspects of process treatment, and this certification should include arithmetic/math and statistical understanding of process operation at a water resource recovery facility. Most likely each core area will address its own area of arithmetic. I suggest that a separate core study area include all wastewater process steps, with a clear understanding of their arithmetic linkage, including the development of formulas, along with more-sophisticated means of calculation incorporating all phases of the process. This verges on process modeling, which can be found in any number of “black box” commercial packages. However, unless an operator understands how the values are calculated, the black box only moves the operator another step away from a true understanding of the process.

Additionally, the facility’s basis of design values intrinsically are tied to arithmetic and could be used as the structure around which the “whole facility” math course would be built. Without this knowledge and how to obtain it, an operator is in the dark as far as his understanding the process for which he or she is responsible. It is my experience that this seems to be the area of greatest weakness in operators, although chemistry and microbiology are not far behind.

Cultivating the ability to write reports

Operators also should demonstrate the ability to write a technology report on a facility’s process streams, including individual components, as well as addressing the facility as a whole. Many journals have printed articles written by operators. This should become the norm rather than the exception. These articles are derived from regular reporting of any one facility’s operation. Report writing also should be one of the core courses required for a water resource recovery facility operator to become certified as an operator–technologist.

Operators will define the future operational quality of our increasingly complex water resource recovery facilities. Those who recognize that there is a need to understand and be curious about the math, microbiology, chemistry, and hydraulics of their facilities will best run these systems.

Operators will build a bridge to their engineering counterparts with the professionalization of their career choice through increased academic training across many disciplines, considerable onsite experience, regulatory licensing, and certification as technologists by an accredited organization. They must not be handmaidens to the engineers but rather technological peers who provide the best of operations from the facilities designed by those engineers and back their operational knowledge with accurate, supportable data.

— John Seldon, WEF Member

September 10, 2013

Featured