Emory University (Atlanta) has opened the doors to the WaterHub™, an ecological treatment facility that reclaims campus wastewater for nonpotable reuse. Photo courtesy of David Fisher, Emory University.

As sustainable water management increasingly becomes important for the metro-Atlanta region, Emory University (Atlanta) is stepping up as a technological pioneer and community leader in that city.

University embodies sustainability

The region struggles with drought, legal disputes over water supply, and U.S. Environmental Protection Agency consent decrees on water quality. So the university opened the doors to the WaterHub™, an ecological treatment facility with 1.5 million L (400,000 gal) per day of capacity to reclaim campus wastewater for nonpotable uses.

In addition to a greenhouse, the system includes this reciprocating wetland with fixed-film microbial ecosystems contained in a series of fill-and-drain wetland cells. Photo courtesy of Fisher, Emory University.

The WaterHub relies on complex adaptive ecosystems to degrade nutrients and pollutants and produce high quality effluent that meets federal, state, and local regulations. Reclaimed water will be used as process water in three central chiller facilities and the campus steam facility as well as to flush toilets in residence halls, according to a university news release.

“Emory is a leader in sustainability, and with this facility we’re taking a major step forward in becoming one of the first in the nation with this technology for cleaning our own wastewater,” said Matthew Early, vice president for Emory University Campus Services.

The “purple pipe” distribution system carries reclaimed water to be used as process water in three central chiller facilities and the campus steam facility as well as to flush toilets in residence halls. Photo courtesy of Fisher, Emory University.

In fiscal year 2011, Emory used an estimated 576 billion L (390 million gal) of water. The university has six major and five satellite utility facilities that provide heating and cooling services for the campus. These facilities are the university’s largest nonpotable water users, accounting for nearly 34% of the total in 2011, the news release says.

But Emory realized that nearly 40% of its demand is for nonpotable water, which can be replaced with alternative supplies. Such a change would save the university millions in water utility costs during a 20-year period, according to Early in the news release.

Treatment technologies and processes combine to produce clean reuse water

Using open space on campus, the university installed a treatment system including a hydroponic greenhouse that spans 195 m2 (2100 ft2). The WaterHub — developed to have a compact footprint and natural aesthetic — both harvests rainwater from the greenhouse and extracts wastewater from the local municipal wastewater system. It treats the water through a proprietary process using technology provided by Sustainable Water (Glen Allen, Va.).

“This [facility] offers an interesting case study for how an institution can move a community toward a bold step in water conservation,” said Ciannat Howett, director of the Emory University Office of Sustainability Initiatives. “It’s exactly the kind of reduction we need to see in order to support a more sustainable future. I think it also shows an important role the university can play in advancing sustainability and engaging in this idea of the campus as a living laboratory, a place of experimentation and engagement and learning.”

The university installed a below-grade duplex pump station to direct influent through a primary screen and into primary treatment. Primary treatment relies on three moving bed bioreactors (MBBRs) located behind the hydroponic greenhouse to reduce the system’s footprint and maintenance. Gases from the enclosed reactors are vented through activated carbon filters to prevent odors from escaping, according to the project overview.

For the next step in the process, hydroponic reactors inside the greenhouse reduce biochemical oxygen demand (BOD) and complete the nitrification process. Vegetation supported on racks cover the reactors. Reactors are aerated with fine-bubble diffusers, which provide the oxygen required for treatment and keep the tank contents mixed. The surface area of the roots of the vegetation provides areas for attached microbial populations to grow. Similar to the moving bed reactors, greater surface area provides more habitat for biofilm formation, resulting in more efficient and stable treatment, the overview says. Vegetation also serves as habitat for beneficial insects and organisms that graze on microbial biomass. Grazing reduces the solids volume and maintains optimal growth rates of microbes, resulting in less solids discharge to the municipal treatment system, the overview says.

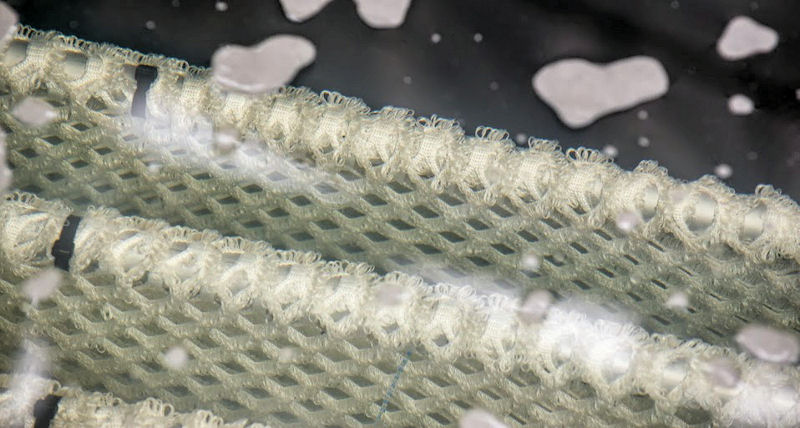

BioWeb, a synthetic root system used in the hydroponic reactors, provides additional habitat for microorganisms. Photo courtesy of Fisher, Emory University.

A layer of lightweight shale-aggregate placed on the racks creates a natural biofilter colonized with bacteria to remove any residual odor. A ventilation system with activated-carbon scrubbers provides a secondary layer of protection in the indoor hydroponic reactors. Processes work together to reduce BOD and ammonium concentrations to levels that meet or exceed standards, the project overview says.

The system also includes a polishing and disinfection stage, which includes a clarifier and ultraviolet disinfection, to remove any remaining solids and dissolved phosphorus. Solids are removed to less than 10 mg/L. A portion of the solids is pumped back to provide bacterial communities at the beginning of the treatment cycle, the project overview says.

Reclaimed water is stored in an underground storage tank. Distribution pumps send the water to various locations across campus, the project overview says.

A small side stream of screened influent is pumped into the reciprocating wetland for additional treatment and research. Photo courtesy of Fisher, Emory University.

The system also includes a reciprocating wetland for additional treatment and research opportunities. A small side stream of about 7570 L/d (2000 gal/d) of screened influent is pumped to the demonstration reciprocating wetland. A fixed-film microbial ecosystem is contained in a series of fill-and-drain wetland cells containing selectively graded aggregates. Fill-and-drain cycling occurs 8 to 18 times a day. Passive aeration provides oxygen to the root zone and promotes rapid growth of plant species, the project overview says.

Educational opportunities abound

“WaterHub can be used as an immersion learning tool to enhance curriculum and advance research in a number of fields,” the project overview says. It can help advance botany, microbiology, engineering, public policy, public health and urban planning, and other curricula. Opportunities also exist for synthetic research projects that would study interactions among different microbiological and ecological systems. The system includes sampling locations throughout and integrated control systems to compile online instrumentation and flow data, the news release says.

— Jennifer Fulcher, WEF Highlights

May 28, 2015

Featured