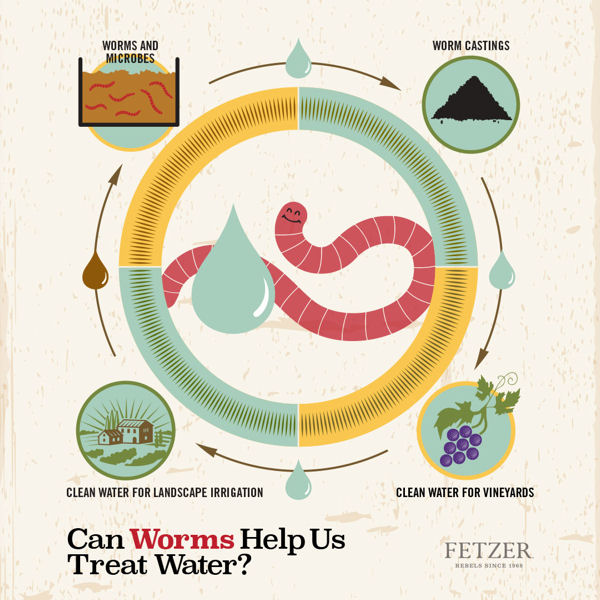

Worm- and microbe-powered system to treat California vineyard’s wastewater in just 4 hours

Earthworms burrow numerous channels that provide passive aeration while digesting large solids and depositing them into microbe-rich castings. Photo courtesy of Sina Pram, BioFiltro (Santiago, Chile).

Very few wineries show the same enthusiasm for their wastewater treatment as for their wines. But Fetzer Vineyards is different. The Hopland, Calif., vineyard and winery is on a mission to prove that it’s possible to produce award-winning wine while using renewable energy, generating zero waste, and — in the coming months —relying on worms to treat its wastewater.

“We are committed to water conservation and employ a number of practices that support our effort to become ‘water positive,’” said Josh Prigge, Fetzer’s director of regenerative development.

An automated irrigation system disperses wastewater across BIDA® system surface. Photo courtesy of Sina Pram, BioFiltro.

The company intends to achieve a “net positive” ecological footprint by 2030. So, when Prigge and others at Fetzer heard about a natural process that uses earthworms and microbes to remove up to 99% of Biochemical Oxygen Demand (BOD) and Total Suspended Solids (TSS) from wastewater, they went all in.

Developed by BioFiltro (Santiago, Chile), the process requires a footprint comparable in size to the aeration ponds it typically replaces but uses a fraction of the energy. It consists of large open-top concrete boxes that house layers of geotextiles, rock, and wood shavings infused with a mix of worms and microbes that match the vineyard’s waste profile.

Worms provide sanitary wastewater treatment in Torres del Paine National Park, Patagonia, Chile. Photo courtesy of BioFiltro.

“Every operation’s wastewater is unique,” said Mai Ann Healy, regional manager for BioFiltro. BioFiltro selected worms from its Fresno, Calif. worm farm and will introduce them to the Fetzer environment over time, in order to acclimate them.

“It takes a couple of months for the worms to adapt and begin reproducing like we want them to,” Healy said. Eventually, billions of worms — as many as 12,000 worms/yd3 — will inhabit the Fetzer system. The worms will spread through the system’s three treatment boxes measuring 36-ft (11-m) wide by 200-ft (61-m) long by 6-ft (1.8-m) deep.

The BIDA® system processes water from wineries, food processors, slaughterhouses, milk processors, dairies, and aquaculture centers. Photo courtesy of BioFiltro.

When harvest season arrives later this summer, the boxes will be irrigated daily with the vineyard’s wastewater. Worms and microbes will feed off of the contaminants that collect in the wood shavings as the wastewater filters through the system.

Four hours later, water leaving the boxes will be safe for irrigation and other nonpotable uses, Healy said. That compares to the 5 to 90 days it can take in typical aeration ponds to process the wastewater.

Worms will process 15-million gal (57-million L) of wastewater a year at Fetzer Vineyards in Hopland, Calif. Photo courtesy of Fetzer Vineyards.

The system is expected to process 15-million gal (57-million L) of wastewater a year for Fetzer, reducing energy consumption by 1-million kWh a year. Every 18 to 24 months, up to 12 in. (30 cm) of nutrient-rich worm castings will be removed from the boxes for use as compost, and fresh wood shavings will be added.

While other American wineries have piloted similar systems, Fetzer is the first that intends to use the process to treat 100% of its wastewater, according to Prigge. Fetzer claims that the system will allow it to reduce energy use for wastewater treatment by 85%.

We can all drink to that.

— Mary Bufe, WEF Highlights

|

Learn about worms’ ability to treat biosolids in the WEF Highlights article, “The Worm Whisperer: Enlisting earthworms to treat biosolids.” |

August 17, 2016

Featured